Kain Kaca Epoxy Lembar Laminasi Kaku (lembar EPGC)

EPGC runtuyan Epoxy Kaca lawon kaku Laminated Lambaran diwangun ku anyaman lawon kaca impregnated kalawan résin thermoseting epoxy, laminated dina suhu luhur sarta tekanan tinggi. lawon kaca anyaman kudu alkali-gratis tur dirawat ku silane coupler. lambar serial EPGC kaasup EPGC201 (NMEMA G10), EPGC202 (NEMA FR4), EPGC203 (NEMA G11), EPGC204 (NEMA FR5), EPGC306 na EPGC308.

Lambaran EPGC (kelas termal: B~H), dihasilkeun nurutkeun IEC60893-3-2. cadar ieu boga kakuatan mékanis alus teuing (tingkat ingetan kakuatan kaayaan termal bisa ngahontal leuwih 50%) dina hawa sedeng atawa kaayaan termal, kitu ogé sipat listrik stabil (résistansi insulasi sanggeus immersion ngahontal 1012Ω) dina kaayaan kalembaban anu luhur. Sareng ogé kalayan daya tahan tegangan anu langkung luhur / tahan tegangan (leuwih 35kV), paralel sareng laminasi. EPGC202, EPGC204 na EPGC306 ogé mibanda sipat retardant seuneu alus teuing. Lambaranana ogé lulus deteksi zat toksik sareng bahaya (kalayan Laporan RoHS).

Dipaké salaku insulasi bagian struktural di Kelas BH motor listrik, alat-alat listrik, nu boga syarat lalawanan seuneu atanapi henteu, atawa aplikasi sejenna.

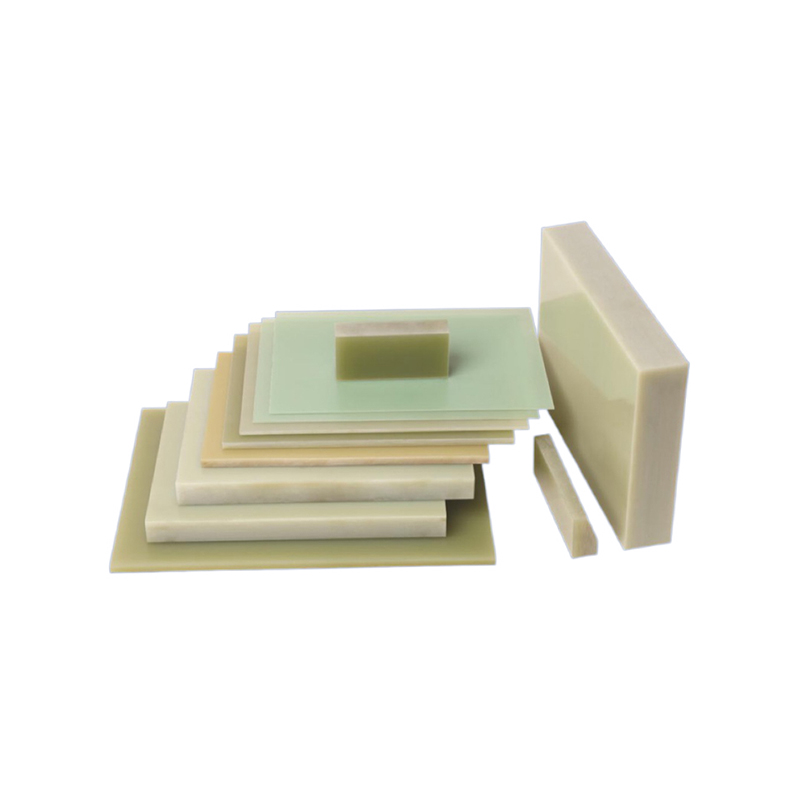

ketebalan sadia:0.30mm ~ 200mm

Ukuran lembar anu sayogi:

1500mm * 3000mm, 1220mm * 3000mm, 1020mm * 3000mm, 1020mm * 2440mm, 1220mm * 2440mm, 1500mm * 2440mm, 1000mm * 2000mm, 1000mm * 2000mm séjén ukuran.

Klasifikasi Jeung Jenis Lambaran Epgc

| Ketik ngaran | Aplikasi & fitur | Kelas termal | |||

| D&F | GB/IEC | NEMA | batur | ||

| DF201 | EPGC201 | G10 | Hgw 2372 | Pikeun mesin, alat listrik sareng éléktron. Kalayan kakuatan anu luhur dina suhu sedeng, résistansi arc anu saé sareng PTI sareng CTI anu langkung luhur | B 130 ℃ |

| DF202 | EPGC202 | FR-4 | Hgw 2372.1, F881 | Sarupa jeung EPGC201, owning nyatakeun retardant seuneu. | B 130 ℃ |

| DF202A | --- | --- | --- | Sarupa jeung DF202, tapi kalawan kakuatan mékanis luhur. | B 130 ℃ |

| DF203 | EPGC203 | G11 | Hgw2372.4 | Pikeun mékanis, alat-alat listrik jeung éléktron. Kalawan kakuatan pangluhurna dina suhu middling | F 155 ℃ |

| DF204 | EPGC204 | FR-5 | Hgw 2372.2 | Sarupa jeung DF203, owning nyatakeun retardant seuneu. | F 155 ℃ |

| DF306 | EPGC306 | --- | DF336 | Sarupa sareng DF203, gaduh résistansi seuneu anu saé, résistansi busur sareng PTI anu langkung luhur. | F 155 ℃ |

| DF306A | --- | --- | --- | Sarupa jeung DF306, tapi owning kakuatan mékanis luhur. | F 155 ℃ |

| DF308 | EPGC308 | --- | --- | Sarupa jeung DF203, tapi kalawan stabilitas termal hadé. | H 180 ℃ |

Syarat Téknis

Penampilan

Beungeut lambaran kedah datar sareng mulus, teu aya gelembung hawa, kedutan atanapi retakan sareng cekap tina imperfections leutik sapertos goresan, dents, jsb. Warnana kedah seragam, tapi sababaraha noda diidinan.

Ketebalan nominal sareng kasabaranUnit: mm

| ketebalan nominal | simpangan | ketebalan Niminal | simpangan |

| 0,5,0,6 0,8,1,0 1.2 1.5 2.0 2.5 3.0 4.0 5.0 6.0 8.0 | +/- 0,15 +/- 0,18 +/- 0,21 +/- 0,25 +/- 0.30 +/- 0,33 +/- 0,37 +/- 0,45 +/- 0,52 +/- 0,60 +/- 0,72 | 10 12 14 16 20 25 30 35 40 45 50 60 | +/- 0,82 +/- 0,94 +/- 1.02 +/- 1.12 +/- 1.30 +/- 1,50 +/- 1,70 +/- 1,85 +/- 2.10 +/- 2,45 +/- 2,60 +/- 2,80 |

| Catetan: Pikeun lembar ketebalan non-nominal anu henteu didaptarkeun dina tabél ieu, simpangan anu diidinan kedah sami sareng ketebalan anu langkung ageung salajengna. | |||

Bending Deflection pikeun LambaranUnit: mm

| Kandelna | Bending Deflection |

| 3.0~6.0 >6.0~8.0 > 8.0 | ≤10 ≤8 ≤6 |

Ngolah mékanis:

Lambaranana kedah bébas tina retakan sareng scraps nalika mesin sapertos sawing, pangeboran, lathing sareng panggilingan diterapkeun.

Sipat Fisik, Mékanis Jeung Diéléktrik

| No. | Pasipatan | Unit | EPGC201 | EPGC202 | EPGC203 | ||||

| nilai baku | nilai has | nilai baku | nilai has | nilai baku | nilai has | ||||

| 1 | Nyerep cai (lambar 2mm) | mg | ≤20 | 8 | ≤20 | 9 | ≤20 | 9 | |

| 2 | Kakuatan flexual | Dina kaayaan normal | MPa | ≥340 | 460 | ≥340 | 500 | ≥340 | 450 |

| (Panjang) | 155 ℃ +/- 2 ℃ | --- | --- | --- | --- | ≥170 | 240 | ||

| 3 | Kakuatan dampak, paralel sareng laminasi (Charpy, kiyeu) | kJ/m2 | ≥33 | 53 | ≥33 | 51 | ≥33 | 50 | |

| 4 | kakuatan listrik, jejeg laminations (dina minyak trafo di 90 ℃ +/- 2 ℃) | kV/mm | ≥11.8 | 17 | ≥11.8 | 17 | ≥11.8 | 18 | |

| 5 | kakuatan listrik, sajajar jeung laminations (dina minyak trafo dina 90 ℃ +/-2 ℃) | kV | ≥35 | 48 | ≥35 | 45 | ≥35 | 45 | |

| 6 | Faktor dissipation diéléktrik (1MHz) | --- | ≤0.04 | 0.02 | ≤0.04 | 0.02 | ≤0.04 | 0,021 | |

| 7 | Konstanta diéléktrik (1MHz) | --- | ≤5.5 | 4.8 | ≤5.5 | 4.7 | ≤5.5 | 4.7 | |

| 8 | lalawanan Arc | s | --- | --- | --- | 182 | --- | 182 | |

| 9 | Résistansi nyukcruk bukti (PTI) | V | --- | --- | --- | 600 | --- | 600 | |

| 10 | lalawanan insulasi sanggeus immersion dina cai | MΩ | ≥5.0x104 | 2,1 x107 | ≥5.0x104 | 1,5 x106 | ≥5.0x104 | 1,1 x107 | |

| 11 | Mudah kaduruk | Kelas | --- | --- | V-0 | V-0 | --- | --- | |

| 12 | Indéks Suhu (TI) | --- | ≥130 | ≥130 | ≥155 | ||||

| No. | Pasipatan | Unit | EPGC204 | EPGC306 | EPGC308 | ||||

| nilai baku | nilai has | nilai baku | nilai has | nilai baku | nilai has | ||||

| 1 | Nyerep cai (2mm) | mg | ≤20 | 11 | ≤20 | 8 | ≤20 | 9 | |

| 2 | Kakuatan flexual | Dina kaayaan normal | MPa | ≥340 | 480 | ≥340 | 460 | ≥340 | 500 |

| (Lengwise) | 155 ℃ +/- 2 ℃ | ≥170 | 260 | ≥170 | 280 | --- | 270 | ||

| 3 | Kakuatan dampak, paralel sareng laminasi (Charpy, kiyeu) | kJ/m2 | ≥33 | 51 | ≥33 | 53 | ≥33 | 52 | |

| 4 | kakuatan listrik, jejeg laminations (dina minyak trafo di 90 ℃ +/- 2 ℃) | kV/mm | ≥11.8 | 16 | ≥11.8 | 17 | ≥11.8 | 18 | |

| 5 | kakuatan listrik, sajajar jeung laminations (dina minyak trafo dina 90 ℃ +/-2 ℃) | kV | ≥35 | 45 | ≥35 | 48 | ≥35 | 45 | |

| 6 | Faktor dissipation diéléktrik (1MHz) | --- | ≤0.04 | 0.018 | ≤0.04 | 0.02 | ≤0.04 | 0.02 | |

| 7 | Konstanta diéléktrik (1MHz) | --- | ≤5.5 | 4.7 | ≤5.5 | 4.8 | ≤5.5 | 4.7 | |

| 8 | lalawanan Arc | s | --- | --- | --- | 182 | --- | --- | |

| 9 | Résistansi nyukcruk bukti (PTI) | V | --- | --- | --- | 600 | --- | --- | |

| 10 | lalawanan insulasi sanggeus immersion dina cai | MΩ | ≥5.0x104 | 3,8 x106 | ≥5.0x104 | 1,8 x107 | ≥5.0x104 | 7,1 x106 | |

| 11 | Mudah kaduruk | Kelas | V-0 | V-0 | V-0 | V-0 | --- | --- | |

| 12 | Indéks Suhu (TI) | --- | ≥155 | ≥155 | ≥180 | ||||

Bungkusan Jeung Panyimpenan

Lambaranana kedah disimpen dina tempat anu suhuna henteu langkung luhur ti 40 ℃, sareng ditempatkeun sacara horisontal dina bedplate kalayan jangkungna 50mm atanapi langkung luhur. Jauhkeun tina seuneu, panas (aparat pemanasan) sareng sinar panonpoé langsung. Kahirupan neundeun cadar nyaéta 18 bulan ti tanggal ninggalkeun pabrik. Upami durasi panyimpen langkung ti 18 bulan, produk ogé tiasa dianggo saatos diuji pikeun mumpuni.

Katerangan Jeung Pancegahan Pikeun Aplikasi

1 Machining wajib sasuai jeung JB/Z141-1979,Métode Machining produk insulasi laminated, sabab cadar boga bédana alamiah dina atribut ti logam.

2 A speed tinggi na motong jero leutik bakal dilarapkeun nalika machining kusabab konduktivitas termal lemah cadar '.

3 Machining jeung motong produk ieu bakal ngaleupaskeun loba lebu jeung haseup. Ukuran anu cocog kedah dilaksanakeun pikeun mastikeun tingkat lebu dina wates anu tiasa ditampi salami operasi. Ventilasi knalpot lokal sareng nganggo masker debu/partikel anu cocog disarankeun.

4 Lambaranana tunduk kana kalembaban saatos dimesin, palapis insulasi ngaleungit disarankeun.

Parabot Produksi

Paket Pikeun Lambaran EPGC